The selection of flexible couplings is a crucial aspect in encoder installations. As experts in encoder technology, we understand the pivotal role that proper coupling plays in ensuring optimal encoder performance and longevity.

Key Characteristics of Flexible Couplings

- Flexibility: Flexible couplings accommodate misalignment between the encoder and the connected shaft, compensating for angular, parallel, and axial misalignments. This flexibility prevents stress on the encoder shaft and bearings, enhancing longevity.

- Torque Transmission: Efficient torque transmission is essential for accurate encoder readings. High-quality flexible couplings ensure minimal power loss during torque transfer, maintaining precision in signal generation.

- Damping Properties: Vibrations can adversely affect encoder accuracy and lifespan. Couplings with damping properties absorb vibrations, resulting in smoother operation and prolonged encoder durability, especially in high-speed applications.

Advantages of Proper Coupling Selection

- Enhanced Reliability: By mitigating misalignment issues and dampening vibrations, suitable couplings enhance the reliability of encoder systems, reducing downtime and maintenance costs for end-users.

- Improved Accuracy: Optimal coupling selection minimizes signal distortion caused by misalignment or vibrations, ensuring precise encoder feedback crucial for applications demanding high accuracy.

- Extended Encoder Lifespan: Reduced stress on encoder components, such as shafts and bearings, significantly extends the lifespan of the encoder, resulting in long-term cost savings for customers.

Key Points for Selection and Installation

- Identify Application Requirements: Consider the application’s operating conditions, including speed, torque, and environmental factors, to select a coupling best suited for the specific demands.

- Evaluate Misalignment Tolerance: Assess the expected misalignment between the encoder and the driven shaft to choose a coupling capable of accommodating such deviations without compromising performance.

- Consider Maintenance Requirements: Select couplings that require minimal maintenance to reduce the overall costs.

Hohner Flexible Couplings

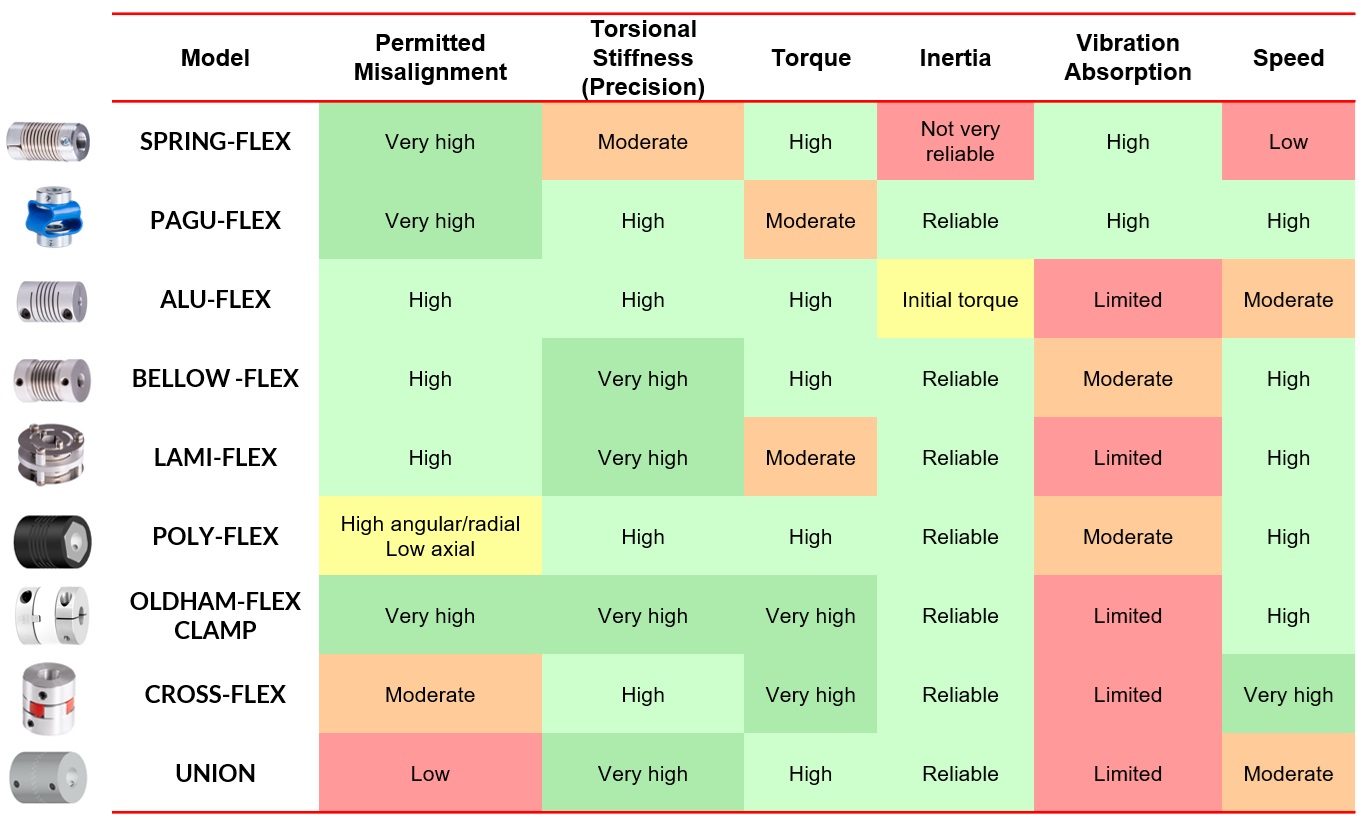

Coupling Selection Criteria

The following table classifies Hohner flexible couplings according to permitted misalignment, torsional stiffness, torque, inertia, vibration absorption and maximum speed:

Best Couplings for Applications

Bellow-Flex

- High precision transmission

- Backlash-free

Pagu-Flex

- Stainless steel option

- Resistant to cleaning agents

Lami-Flex

- High rotation speed

- Great torsional rigidity