At Hohner Automation, we are committed to innovation and quality, offering a new range of encoders specifically designed for the food industry. Our robust encoders ensure optimal performance in demanding environments, providing the efficiency and precision that the food sector requires.

Robust Encoders for the Food Industry

Our INOX series of encoders is made with high-quality materials that meet the stringent standards of the food industry:

- 19K and 10K Series: Designed for the most extreme environments, these encoders are made from stainless steel AISI 316 and have an IP69K protection rating, making them perfect for intensive high-pressure and high-temperature cleaning processes.

- 30I and 50HI Series: These encoders are made from stainless steel AISI 304 and 304L, with an IP67 protection rating, making them ideal for applications requiring durability and corrosion resistance.

- Compatible Accessories: We offer coupling hoods and insulating flexible couplings to ensure compatibility and optimal performance in each application.

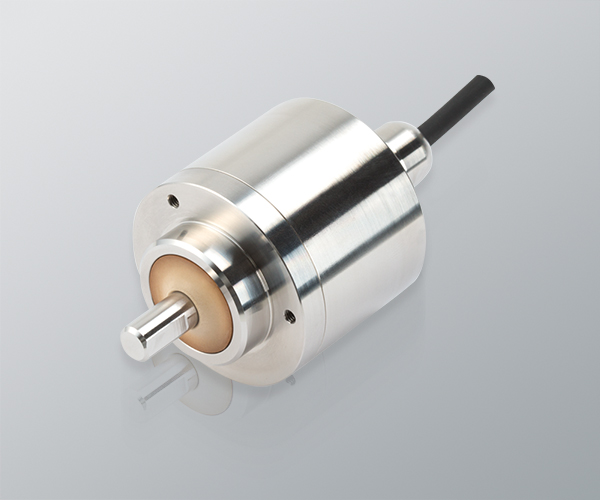

SERIE 10K

HIGH RESOLUTION INCREMENTAL SOLID SHAFT ENCODER FOR INDUSTRIAL APPLICATIONS

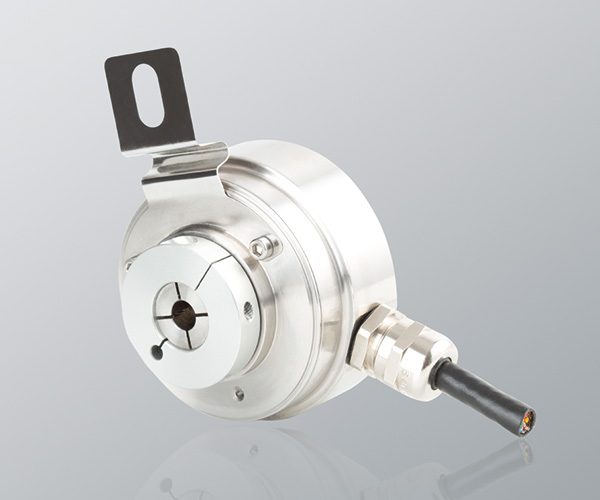

SERIE 19K

HIGH RESOLUTION INCREMENTAL HOLLOW SHAFT ENCODER FOR INDUSTRIAL APPLICATIONS

SERIE 30 IP67 INOX

HIGH RESOLUTION INCREMENTAL SOLID SHAFT ENCODER FOR HEAVY DUTY INDUSTRIAL APPLICATIONS

SERIE 50HI INOX

COMPACT INCREMENTAL BLIND HOLLOW SHAFT ENCODER FOR DEMANDING INDUSTRIAL APPLICATIONS

High-Quality Materials for Robust Encoders

Our robust encoders are built with materials that guarantee a long service life and excellent resistance to the most adverse conditions, essential characteristics for the food industry:

- Stainless Steel AISI 304 and 316: With high corrosion resistance, these materials ensure durability and compliance with hygiene standards.

- Anodized Aluminum: Provides additional protection in aggressive environments.

- Effective Sealing Components: We use PEEK-PTFE and NBR rubber outer seals, along with VMQ silicone gaskets, to ensure perfect sealing and prolong the encoder’s life.

Certifications and IP Protection Ratings for the Food Industry

Our encoders are designed to offer the highest level of protection, meeting the most stringent certifications in the food sector:

- IP67: Protection against temporary immersion, essential for environments with the presence of liquids.

- IP69K: Resistance to high-temperature and high-pressure water jets, ideal for intensive cleaning processes performed in the food industry. Visit our blog post about encoders with IP69K protection in the blog entry Is an IP69K Encoder Necessary?

Applications of Encoders in the Food Industry

Our robust encoders are essential for a variety of applications in the food sector, ensuring the precision and efficiency needed to enhance production processes:

- Bottling Lines: Precise control of position and speed from blow molding and stretching to labeling.

- Fruit and Vegetable Lines: Optimization of processes such as peeling, cutting, and centrifuging, ensuring the quality of the final product.

- Meat Processing Lines: Specialized encoders for cutting, sorting, and stuffing, meeting the highest hygiene standards.

Success Stories in the Food Industry

We have implemented our encoder solutions in various food sector companies, achieving exceptional results in efficiency and precision:

- Sterilization Machinery: Multi-turn absolute encoders to improve automation and position control.

- Meat Deboning: Compact, water-resistant encoders to operate at high speed and maintain cleanliness.

- Sausage Drying: Stainless steel AISI 316 encoders with plastic and INOX couplings to ensure hygiene and durability.

At Hohner Automation, we continue to lead innovation in encoders for the food industry, offering robust and high-precision products that meet the highest standards of quality and durability.